Votives are arguably one of the easiest kinds of molded candles to make. They add a great deal of charm to just about any setting. The typical votive will burn for approximately 15 hours and will consume just about all of the wax that was used to create it. A properly crafted votive will liquefy to some degree as it burns. This is necessary to achieve good scent throw. Votives are not intended to be free standing candles. Therefore it is important to burn votives only in a holder that is intended for votives. You will need:

- Wax suitable for votives

- Wax additives (only if needed for your wax formulation)

- Fragrance oil (optional)

- Dye (optional)

- Pre-tabbed wicks suitable for votives (36-24-24 zinc core used here)

- Metal Votive Molds

- Mold release spray (optional)

- Pouring pot

- Thermometer

Instructions:  Step 1. Prepare your melted wax mixture.

Step 1. Prepare your melted wax mixture.

You should be able to review these instructions while your wax is melting. Before continuing, set up a double boiler to melt your wax. A good target temperature for votives is 175° F. Once your wax has completely melted, add any additives you have selected and mix thoroughly, but try to avoid introducing air into the mixture.

Add them in the following order:

- Additives such as vybar or stearic acid(but only if needed)

- Fragrance Oil

- Dye (this is done last so that you get visual confirmation that everything else has mixed well with the wax)

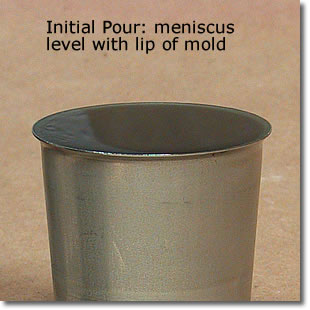

Before pouring your wax, you may want to lightly coat your molds with a very thin film of mold-release agent such as silicone spray or a Pam-type cooking spray. This helps aid the release of the finished candle from the mold. However, it is really only needed with new molds.  Step 2. Votives: Initial Wax Pour Place your votive molds on a newspaper-lined surface to catch any spills. With your wax at the proper pouring temperature (about 175° F), fill your votive molds to the lip of the mold. The objective here is to get the wax just up to the lip without over flowing. If you pour to a level lower than the lip, you may get seam lines in your finished candle. Care should be taken to minimize the number of bubbles introduced while pouring.

Step 2. Votives: Initial Wax Pour Place your votive molds on a newspaper-lined surface to catch any spills. With your wax at the proper pouring temperature (about 175° F), fill your votive molds to the lip of the mold. The objective here is to get the wax just up to the lip without over flowing. If you pour to a level lower than the lip, you may get seam lines in your finished candle. Care should be taken to minimize the number of bubbles introduced while pouring.  Save about 20% of your wax for the re-pour at a later step. Do not return it to the heat source.

Save about 20% of your wax for the re-pour at a later step. Do not return it to the heat source.  Step 3. Add Pre-tabbed Wicks. Wait for your wax to cool for a short period of time. While it is cooling, prepare your wicks by straightening them. They do not need to be perfectly straight at this point; a loose approximation of “straight” is fine. Once the wax just begins to congeal, insert your pre-tabbed wicks. The tab will “stick” to the bottom when it touches. Care should be taken to position the tab roughly in the center of the mold.

Step 3. Add Pre-tabbed Wicks. Wait for your wax to cool for a short period of time. While it is cooling, prepare your wicks by straightening them. They do not need to be perfectly straight at this point; a loose approximation of “straight” is fine. Once the wax just begins to congeal, insert your pre-tabbed wicks. The tab will “stick” to the bottom when it touches. Care should be taken to position the tab roughly in the center of the mold.  FYI: Why wait for the wax to begin congealing? At the temperature of the congealing point, the wax is cool enough that it will not interfere with the firmness of the primed wick. It also is the temperature that allows the metal tab to “stick” to the base of the mold. At higher temperatures, the wick can be a little more difficult to manage (not impossible).

FYI: Why wait for the wax to begin congealing? At the temperature of the congealing point, the wax is cool enough that it will not interfere with the firmness of the primed wick. It also is the temperature that allows the metal tab to “stick” to the base of the mold. At higher temperatures, the wick can be a little more difficult to manage (not impossible).  Once the tab has stuck to the base of the mold, it is very easy to manipulate the wick to straighten it. Sometimes you may wish to wait a few moments to allow the metal tab to form a stronger bond with the base of the mold before attempting to straighten the wick. During the cooling process, the shrinking wax may pull the wick off-center. If this occurs, simply apply a light tug to straighten the wick from time to time. Do not use so much force as to free the metal tab on the base.

Once the tab has stuck to the base of the mold, it is very easy to manipulate the wick to straighten it. Sometimes you may wish to wait a few moments to allow the metal tab to form a stronger bond with the base of the mold before attempting to straighten the wick. During the cooling process, the shrinking wax may pull the wick off-center. If this occurs, simply apply a light tug to straighten the wick from time to time. Do not use so much force as to free the metal tab on the base.

Allow your wax to completely cool before proceeding to the next step. This may take 3-4 hours.

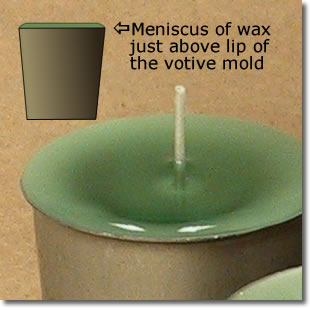

4. Re-pour Wax When the wax has completely cooled, it will have shrunken a bit, leaving a sink hole that needs to be filled. Melt down the wax that you saved from step 2 above. This time, your target pouring temperature will be 10-15 degrees hotter than the initial pour (pour at about 190 deg. F for this step). This increased temperature is to facilitate adhesion between layers. Once your wax is at the proper temperature, fill the molds to a level just slightly above the lip of the mold. Care should be taken to avoid spills.

4. Re-pour Wax When the wax has completely cooled, it will have shrunken a bit, leaving a sink hole that needs to be filled. Melt down the wax that you saved from step 2 above. This time, your target pouring temperature will be 10-15 degrees hotter than the initial pour (pour at about 190 deg. F for this step). This increased temperature is to facilitate adhesion between layers. Once your wax is at the proper temperature, fill the molds to a level just slightly above the lip of the mold. Care should be taken to avoid spills.  Allow your candles to completely cool.

Allow your candles to completely cool.  5. Remove Votive from Mold Once your votives are completely cool, remove them from the mold. They will usually slide right out without any difficulty if they are completely cool. If you attempt to take them out too soon, it will be more difficult to finally get them out. If they are difficult to remove from the molds, place them in the freezer for about 5 minutes. This will usually do the trick. If they are still difficult, place them back in the freezer for another 5 minutes and try again. Also, for very stubborn candles, it sometimes helps to gently press the sides of the mold inward as you “roll” the mold in the palms of your hands. 6. Enjoy Always burn votives in a votive holder. Remember that they are not intended to be free-standing candles and they will liquefy

5. Remove Votive from Mold Once your votives are completely cool, remove them from the mold. They will usually slide right out without any difficulty if they are completely cool. If you attempt to take them out too soon, it will be more difficult to finally get them out. If they are difficult to remove from the molds, place them in the freezer for about 5 minutes. This will usually do the trick. If they are still difficult, place them back in the freezer for another 5 minutes and try again. Also, for very stubborn candles, it sometimes helps to gently press the sides of the mold inward as you “roll” the mold in the palms of your hands. 6. Enjoy Always burn votives in a votive holder. Remember that they are not intended to be free-standing candles and they will liquefy

Hi Im a novice at candle making and just made my first batch of parrafin wax candles following all the instructions as listed .. On removal of the candle from mould, they are wet? The candle itslef looks ok, but I dont seem to be able to find any information on this? I was wondering if you might have an answer please. thank you. Kind regards Denise

When you say “wet” — do you mean like oily-wet? What type of wax are you using and what is your percentage of fragrance oil? Most waxes can easily accept an ounce of scented oil per pound of wax by weight. If they’re oily, then most likely, you used too much scent.